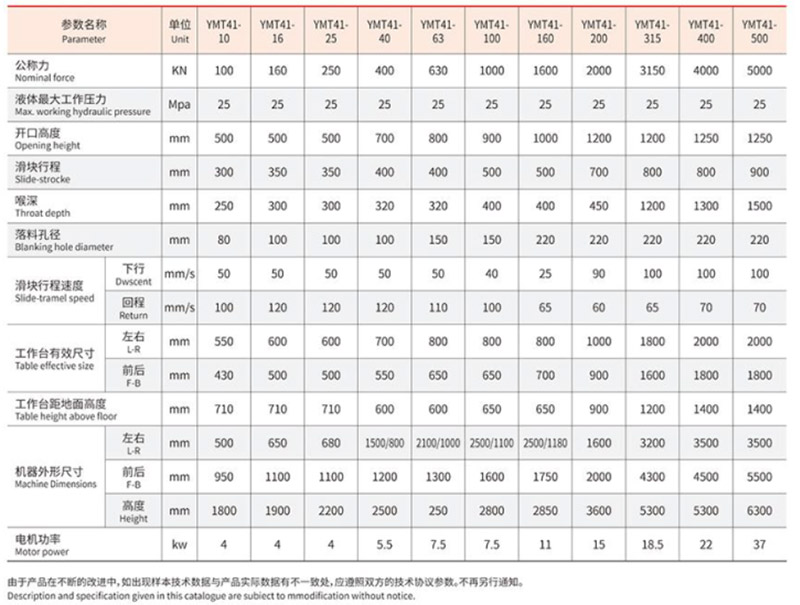

Technical Parameters

Performance Characteristics

Single-column hydraulic press, the body is C-type single-arm structure, welded by carbon dioxide protection welding, after welding through the high-temperature tempering furnace treatment, in order to eliminate the internal stress of the frame after welding. Hydraulic system is located in the body, beautiful appearance, easy to operate.

Field of application

It is mainly applied to the correction, stretching, molding and pressing of metal materials, etc. It can also be used for the correction of shaft parts, the press-fitting of sleeve parts and the shaping and trimming of metal products.

Optional accessories

This series of presses is equipped with independent hydraulic and electrical control system, which is centrally controlled by push button, and can realize two kinds of molding process, namely, fixed range and fixed pressure, with pressure display and functions of stroke and pressure adjustment, etc. The series is also equipped with guide column guide, so as to improve the precision of products. Moreover, this series is equipped with guide column guiding, which can improve the precision of the products. Moreover, the guide column and piston rod are hard-chrome plated on the surface after quenching, which ensures the wear resistance and better roughness of the surface, and the oil inlet of the oil pump is equipped with a unique filtering device, which ensures the service life of the oil pump and the valves.

Imported high-pressure hose is used for oil circuit connection, which greatly reduces the noise of the machine. In addition, according to user requirements, another configuration of imported PLC, grating protection and human-machine interface (touch screen) and other advanced components. For customer's special requirements, we can special design and production, ****** limit to meet the customer's production process requirements.